In October 2015, Dyson acquired the battery startup Sakit3 for

$90 million after an investment of $15 million, which was taken as preparation

for its entry into the electric vehicle industry.

Through this acquisition, Dyson takes the reins of three core

technologies of cordless vacuum cleaners. Take Dyson’s latest V10 products as

an example:

1. Cyclone technology

2. High speed digital motor

3. Lithium battery and BMS management

The cyclone technology patent is the core of the Dyson vacuum

cleaner from the beginning, while the latest V10 digital motor is the kernel of

the current cordless vacuum cleaner. With the advent of high-speed digital

motor, the performance of the cordless vacuum cleaner approaches that of the

ordinary vacuum cleaner. What needs attention is that lithium battery and

battery management system (Battery management system, BMS for short) is also

the core of cordless vacuum cleaners.

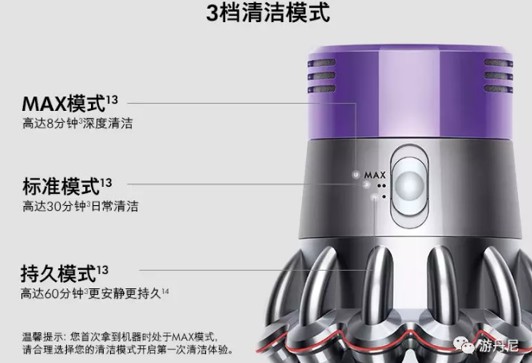

With huge energy consumption, the battery life is complained

about the most as to high-speed digital motors. Only when using the latest

lithium battery and BMS, the model can run for 8 minutes on the high gear, and for

60 minutes at most. Without popularity of lithium battery, the era of cordless

vacuum cleaners will come soon.

What battery is used on the vacuum cleaner before? Let’s have a

brief look:

1. Nickel-cadmium battery:

Nickel-cadmium battery NiCd was applied to the earliest vacuum

cleaners, characterized by small capacity, long charging time and short use

time.

The early models powered by nickel-cadmium battery feature “10-hour

charging and 5-minute duration”. The nickel-cadmium battery has a memory

effect. If not completely discharged, it cannot release all the electricity when

used next time. It also does harm to the environment. Since January 1, 2016,

the European Union has banned the use of nickel-cadmium batteries in power

tools and small appliances.

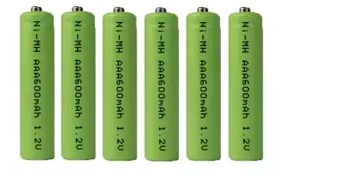

2. NiMH battery:

The nickel-hydrogen battery NiMH boasts a larger capacity, lower

memory effect, and lower environmental pollution than nickel-cadmium battery. Despite

the price rise, it has quickly become the mainstream model.

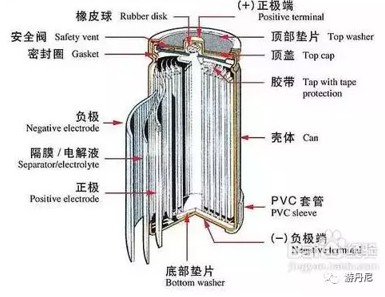

3. Lithium battery

The lithium-ion battery went popular, gradually replacing the

nickel-hydrogen battery and becoming the main force. Compared with nickel-metal

hydride batteries, lithium batteries have higher energy density (1.5-2 times

that of nickel-hydrogen batteries), lower self-discharge rate and zero memory

effect. Lithium batteries mainly work by relying lithium ions to move between

the positive and negative electrodes. Lithium-ion batteries use an embedded

lithium compound as electrode materials. Currently positive electrode materials

for lithium ion batteries are: lithium cobalt oxide (LiCoO2), lithium manganate

(LiMn2O4), lithium nickelate (LiNiO2) and lithium iron phosphate (LiFePO4).

Current lithium batteries are generally classified into

cylindrical, square lithium batteries and soft case lithium batteries (polymer

lithium batteries) depending on the package.

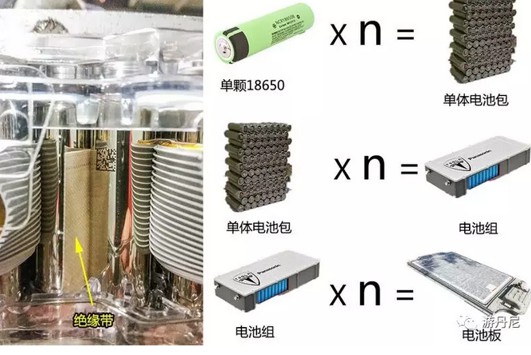

1. Cylindrical lithium battery

The cylindrical lithium battery was invented by Sony Corporation

of Japan in 1992. With stable quality, it is relatively safe in use and has

favorable expansion performance. At present, the common models of cylindrical

lithium batteries are 14650, 17490, 18650, 21700, 26650, etc.

Now the Tesla electric car uses more than 7,000 Panasonic 18650

batteries in series-parallel connection.

Sony did not benefit from the development of electric vehicles

despite it is the inventor of lithium battery. In 2016, Sony packed and sold

the lithium battery business to Murata Manufacturing Japan. Murata also took

over the customer resources of Sony Lithium, including the reputed vacuum

cleaner manufacturer Dyson.

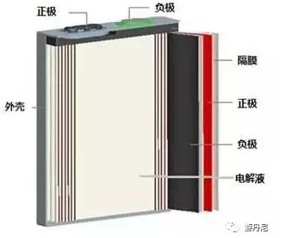

2. Square lithium battery

Square lithium battery usually refers to the square battery of

aluminum shell or steel shell. The square battery is relatively simple in structure

and high in the relative energy density. For a cylindrical monomer, the energy

density ratio can reach 215WH/Kg, based on the current domestic mainstream

18650 (1.75AH).

For the square monomer, the energy density ratio is up to 205 WH

based on 50 AH. As to the system group rate, 18650 stays around 60%, while the

square stays around 70%. Then the energy density ratio of the 18650 battery

system is about 129WH/Kg, while the system energy density ratio of the square

battery pack is about 143WH/Kg.

As the monomer battery cell is larger, the uniformity of the

square cell is better than cylindrical cells of larger quantity with the same

power.

However, with high customization, there are currently thousands

of models on the market, and the processes can’t be easily unified.

3. Soft pack lithium battery (polymer lithium battery).

The soft-pack lithium battery also called a polymer lithium

battery is a polymer shell on a liquid lithium-ion battery. The flexible

packaging material is usually divided into three layers and an outer resist

layer (generally an outer protective layer composed of BOPA or PET), barrier

layer (intermediate aluminum foil) and inner layer (multifunctional high

barrier).

The soft pack battery excels in safety, to bulge and crack in

case of safety hazard, instead of blast like a steel shell battery. It is now

applied to most of the mobile phones. What is more, the soft pack lithium

batteries are light in weight and large in capacity. Yet it has poor

consistency, high cost, and easy liquid leakage.

Nowadays, vacuum cleaners and power tools mostly adopt cylindrical

batteries, especially 18650 lithium batteries, with a diameter of 18mm, a length

of 65mm and cylindrical shape.

To learn more about manufacturing of the 18650 lithium battery,

please refer to this article.

Now the 18650 lithium battery has the risks of explosion, as

shown in the video below:

It is clear the single-cell lithium battery is of powerful blast

force. Usually 6 cells are applied. If a short-circuit explosion occurs at the

same time, the power is beyond measure.

Can this explosion be avoided?

Unfortunately, there is currently no way to completely avoid it.

Even the imported batteries such as Panasonic, LG, Samsung are not 100%

risk-free, let alone locally made products.

A friend specializing in power tools told me that a client in

Germany specially sets a lithium battery emergency team to handle lithium

battery related problems. Once receiving complaints about the lithium battery explosion/self-ignition,

they will hurry home of the customer, give hundreds of thousands of dollars as compensation,

and clean up explosion traces, in case of the product problem being posted to the

media or social networks.

To tackle this problem, all major companies seek help of

reliable agents in development of BMS-Battery Management System, the core

technology of the lithium battery pack.

A: Why is BMS necessary?

Q: As single batteries vary in the capacity, the location and

working conditions. Without a unified battery management system, it is easy to

overcharge and over-discharge a certain battery, and result in failure of the entire

battery pack. BMS targets monitoring and management of the single battery.

BMS on some electric vehicles can function as below:

1. Monitor the voltage, current and other states of each

battery, ensure discharging of the high voltage battery and continuous charging

of the low voltage battery to maintain the balance and slow down the overall

attenuation of the battery pack, which matters most to the BMS;

2. Estimating the state of charge (SOC) of the current battery

pack, that is, the remaining battery power, by monitoring the voltage, current

and other parameters, ensuring that the SOC is maintained within a reasonable

range;

3. Monitor the temperature of each part of the battery pack and

control the cooling of each part with the built-in temperature control system

to maintain the most suitable working temperature range of each part.

4. Monitor the battery pack and warn of leakage and other

problems.

5. Develop real-time communication with other systems in the car

to provide parameters of the current battery status;

6. Collect and archive historical data of each battery for

future offline analysis.

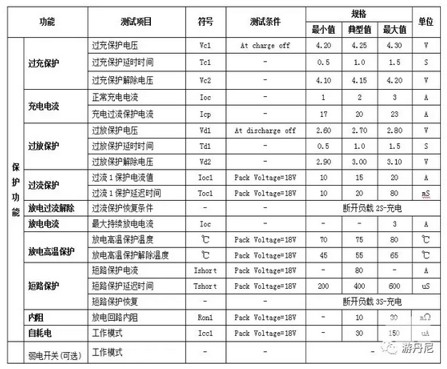

The BMS on our vacuum cleaners and power tools is relatively

simple, generally of the following functions (pictures from the network):

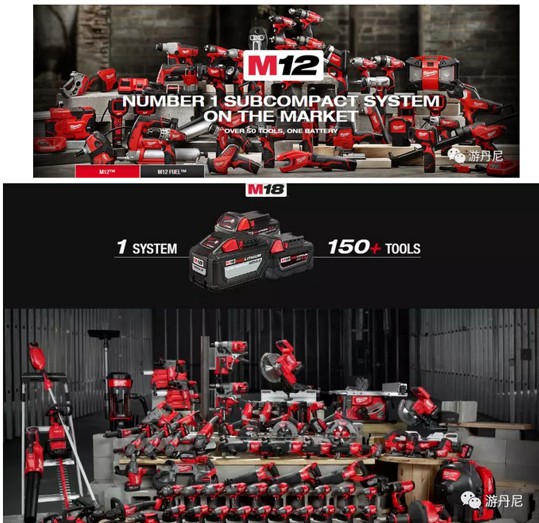

In the current power tool industry, lithium battery products are

beginning to become platform-based. Taking TTI products as an example, lithium

battery products are now mainly divided into 12V and 18V platforms. Hundreds of

products on the same platform can share batteries.

From the product perspective, the versatile battery platform

reduces development costs, while the unified battery platform significantly

reduces the cost of BMS.

When it comes to sales, the unified battery platform enables

universal use of batteries in different power tools. Power tools purchasers

will first consider battery packs that match the existing products at home. As

a result, large businesses will grow larger, while small ones will hardly

threaten them.

As such, Bosch launched a cordless vacuum cleaner Unlimited armed

with a 18V battery, which highlights universal battery for the vacuum cleaner

and power tool, as specified in this article (article link). Yet, vacuum

cleaner stylings change a lot, making a battery pack hardly match with multiple

models.

Realizing the significance of lithium batteries in the era of cordless

vacuum cleaners, several major vacuum runners are developing their production

line of battery pack.

Guangdong Donlim has vigorously developed cordless vacuum

cleaners in the past few years. It now starts to produce battery packs itself.

The industry leader LEXY has rolled out its own lithium battery production line

reputedly. Third-party motor manufacturer Cinderson leads in the development of

brushless motors. I heard that it also rolled out battery pack production line.

Cinderson proves daring to invest in the cordless era.

Below are my insights on the development of lithium battery

packs.

1. Lithium battery packs play a big part in pricing of the power

tools. Is it possible for a mark down? The battery core is of relatively

transparent cost and the price, restrained by raw materials. Only BMS of the

battery pack is most likely to mark down. If the battery pack is used

universally, the BMS of the battery pack will be half priced.

2. Now the brushless vacuum cleaner can work for 10 minutes on

the high gear, hardly to be improved with no breakthrough in battery energy

density and technology. Some plants are testing 21700 batteries applied to

their products. Yet as the 21700 battery is larger than 18650, as with the size

and weight, the final product modeling volume is affected. Data of 21700 applied

to Tesla Model 3 are shown below.

3. Going cordless is a trend, applicable to products more than

vacuum cleaners.